04 December 2023 Understanding Glove Standards & Cut Ratings

How To Understand NEW EN388:2016 Glove Standards

What Is EN388:2016?

EN388:2016 is a European standard that outlines the criteria, testing procedures, and labeling specifications for safety gloves intended to protect against mechanical hazards during various work activities.

The standard incorporates six specific tests crafted to evaluate both the glove and its fabric or layers.

While EN388 may not be an Australian Standard, it has evolved to serve as the benchmark for performance ratings within the glove manufacturing and safety industry since its inception.

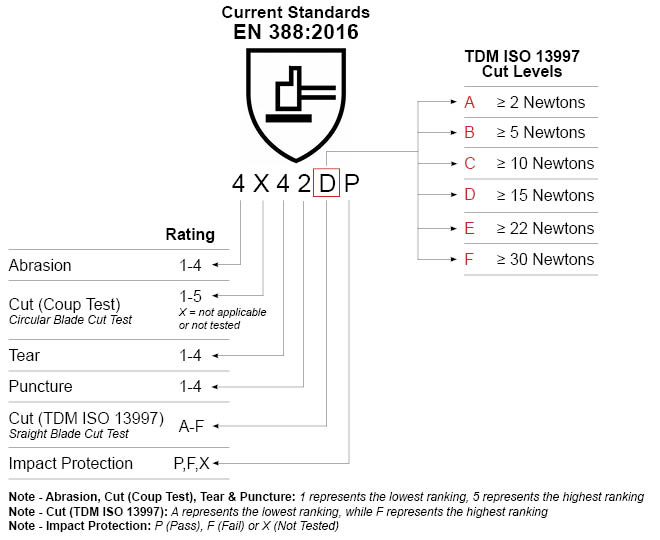

What Do The Numbers On Safety Gloves Mean When Tested To EN388:2016 Standards?

In accordance with this standard, abrasion resistance, cut resistance, tearing strength, puncture resistance, and impact protection characteristics undergo testing.

- Abrasion Resistance: Testing the resistance of the safety glove to abrasion involves subjecting the material to sandpaper under pressure. The benchmark is determined by the number of cycles required to create a hole in the material.

- Cut Resistance (Coup Test): Assessing the blade cut resistance of a safety glove involves the use of a rotating circular blade that cuts through the glove at a consistent speed. The benchmark is established by comparing the glove's performance with a reference material, resulting in an index.

- Tearing Strength: Examining tear resistance involves initially slitting the material of the safety glove, with the benchmark being the force required to tear the material.

- Puncture Resistance: Assessing puncture resistance involves piercing the glove with a nail, with the force applied serving as a benchmark.

- Cut Resistance (TDM ISO 13997): This method involves testing with a cutting knife where the cut material dulls the blade during the process. The knife cuts at a consistent speed but with increasing force until breakthrough of the cut protection material occurs. The level of protection is measured in Newton, representing the force required for a cut through a 20mm length.

- Impact Protection: The presence of impact protection in the glove is indicated by the letter P as the sixth and final symbol. If there is no P sign, it signifies that no impact protection is being asserted.

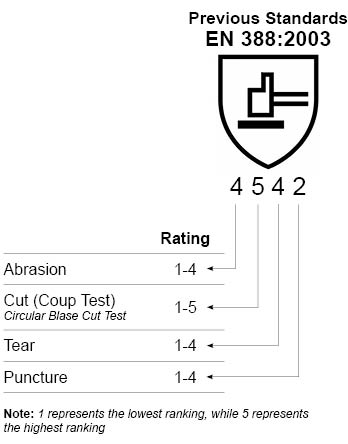

What Is EN388:2003 And How Does It Differ To EN388:2016?

This is the old version of the standard against mechanical risks.

The differences compared to the 2016 version include alterations in the paper grid for the abrasion test and the procedure for testing cut-resistant fibers. Also not applicable to test impact protection.

Numerous protective gloves available in the market are still labelled based on the outdated version of this standard. However, it's important to understand that gloves marked with the older version are equally reliable as those marked with the updated standard.

Its crucial to understand that the gloves' performance remains consistent; what has changed is the way of testing the performances.

What Do These Changes Mean For Users?

When considering the performance, quality, and usability of safety gloves, there's no real change for the end user. However, it is crucial to understand that concerning 'Cut Resistance,' there are now outlined levels (A-F) within what was initially identified as a 'Cut 5 Glove.' The appropriate choice depends on the user's specific cut resistance needs, influencing the required level of Cut 5 Resistance.

- All gloves with EN388:2003 certifications will remain valid, however gloves can no longer be manufactured under this standard.

- Every product will maintain its current performance level assignment.

- The accurate choice of gloves still relies on the specific application or cut protection risk in real-life, practical scenarios.